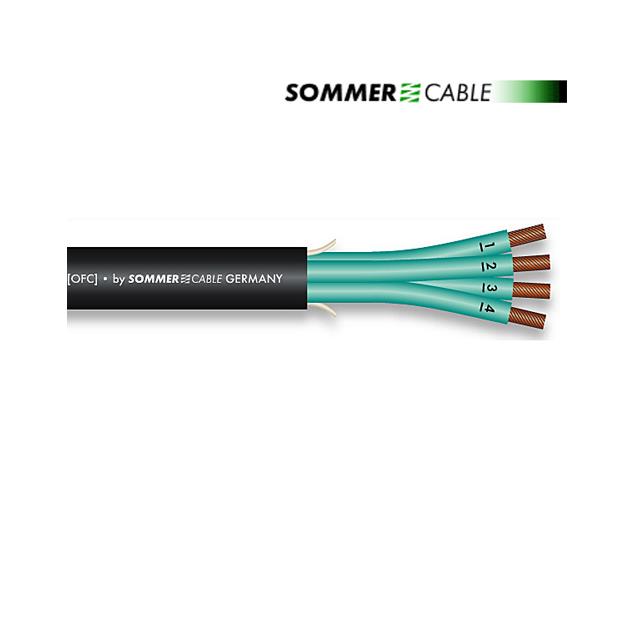

Sommer Cable SPM440 - SC-ELEPHANT ROBUST - Speaker cable (1 m / 4x4 qmm / OFC / black)

You save: 49 %

Highlights / Advantages

| Loss-free transmission due to special stranding | ||

| Highly flexible and suitable for the stage, easy to wind | ||

| Compatible with CA-COM 8-pin, NL8-, LKS19-, EP5-connectors | ||

| Easy handling with good insulation and numbered wiring |

Properties

|

||

| Analog cables are used to transmit low frequency audio signals and to connect microphones, speakers and many other audio components. |

||

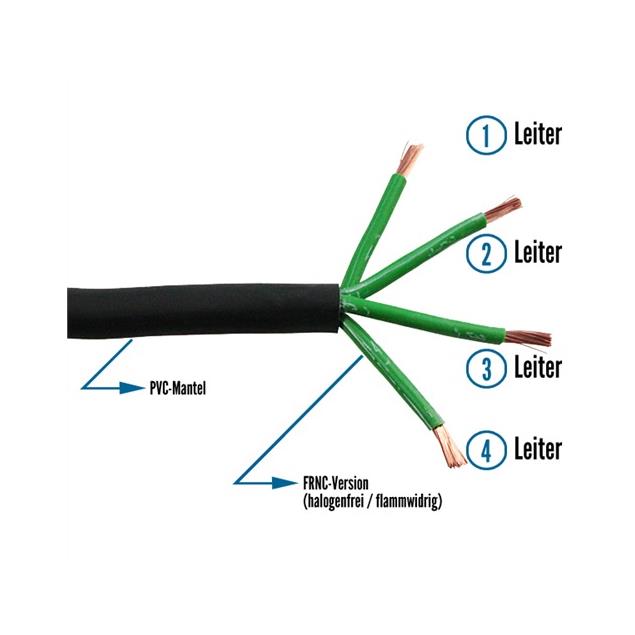

| In case of fire this cable will not develop any gases that are poisonous to humans, e.g. chloride. This is often a requirement in public buildings. But careful! A halogen-free cable is flammable and normally a flame-resistant effect, known as FRNC (halogen-free and flame-resistant), is required. Low in fumes If cables or wiring with insulation or jackets (e.g. made of PVC) containing chlorine burn, dense black fumes will be the result. Halogen-free cables or wiring only develop approx. a tenth of the fume density when compared to PVC-cables or wiring – they are thus considered to be low in fumes. |

||

| These cables comply with the generally valid fire protection guidelines. They are halogen-free and flame-resistant. This guideline is classified. EXPLANATION of testing procedures according to VDE 0472, Part 804: FRNC Test Type A A cable sample measuring 60 cm in length is vertically suspended in the center of a metal box (height 1200 mm x width 300 mm x depth 400 mm). A gas burner with a de? ned ? ame is ? xed, so that its axis is tilted by 45° in reference to the vertical. The ? ame hits the cable sample about 100 mm from the lower end. The ? ame hits until the conductor or the top most metal shielding emerges, but no longer than 20 seconds. The test is successful if the test sample did not burn or if the ? ame that resulted extinguishes itself and the damage caused by the heat of the ? ame did not reach the upper end of the test sample. FRNC Test Type B A cable sample measuring 60 cm in length is vertically suspended in the center of the metal box (height 1200 mm x width 300 mm x depth 400 mm). A gas burner with a de? ned ? ame is ? xed, so that its axis is tilted by 45° in reference to the vertical. The ? ame hits the cable sample about 100 mm from the lower end for about 1 – 2 minutes, depending on the weight of the sample. The test is successful if the test sample did not burn or if the ? ame that resulted extinguishes itself and the damage caused by the heat of the ? ame did not reach the upper end of the test sample. FRNC test type C Cable samples, each measuring 360 cm in length, are fastened side by side to a ladder-like test rack. This test rack is inserted vertically into a kiln, at a distance of 150 mm to the back of the kiln. The cable samples are reached by the ? ame at a height of approx. 60 cm, at a temperature of approx. 800 °C, by a burner of approx. 250 mm in width. The exposure time is 20 minutes. The test is successful if the ? ame that resulted extinguishes itself and the damage caused by the heat of the ? ame did not reach the upper end of the test sample. |

||

| A PUR-jacket is extremely tough, especially resistant to the cold (–40 °C), yet easy to wind even at minimal temperatures. At SOMMER CABLE we usually give our cables a halogen-free PUR-jacket, which is, aside of the advantages mentioned above, very tolerant to heat and sunlight. This jacket is a little more expensive than the standard PUR-mixture, but is meanwhile required and preferred by almost all broadcasting companies and professional installers. |

||

| This seemingly unimpressive identification code stands for an important description of continuous function in case of fire. This fire protection class is based on DIN VDE 0815/DIN VDE 4102 (Part 12) and stands for improved performance in case of a fire, compared to e.g. common FRNC-cables. In compliance with this norm, E30 guarantees continuous function for 30 minutes. Please note that it is not possible to manufacture all cables accord. to E30 or even E90, because the insulation on some cables does not comply with the norm stated above. |

||

| All cables identified with AQUA are watertight up to a water pressure of 20 bar. The special PUR-jacket keeps water and other fluids from penetrating and prevents longitudinal dispersion in case of cable damages. The watertight jacket is also robust enough to handle the installation of high-pressure end sockets inevitably needed to prevent moisture from penetrating. Penetrating water not only speeds up the oxidation process, but will, due to the capillary action, alter the damping and other relevant electrical values. Here, video cables and other coaxial cable types are especially jeopardised, e.g. on monitoring cameras or monitors.Starting at a length of 2,000 m almost all our cables can be manufactured with this jacket. Prices and delivery times are available upon request.Caution: Watertight does not mean “oceanic water tight” or “salt water tight”! |

||

| SOMMER CABLE mostly uses oxygen-free (OFC) or low-oxygen copper. For your information: Copper has a specific resistance of 0.0178 ? per meter, at a diameter of 1 mm². The purer the metal, the smoother it is (high bending cycles!) and the more consistent this value will remain over the years. |

||

| The Pur Master Blend has a jacket mixture on a polyurethane basis, especially developed for SOMMER CABLE. The jacket on the PMB is resistant to notching and cold temperatures (–40 °C) and free of adhesion with a surface that is easy to clean. PMB offers the toughness and temperature resistance of PUR and the ? exibility of PVC. PMB is not halogen-free or ? ame-retardant. |

||

| A granular mix on a PVC-basis, also exclusively developed for SOMMER CABLE. S-PVC is a super soft PVC with the “feeling“ and ? exibility of a soft rubber hose cable, but with signi? cantly more resistance to notching and cold temperatures than most standard PVC-jackets. While most jacket mixtures already start tearing during mobile application of –10 °C, the S-PVC withstands temperatures of –30 °C. |

||

Description of Article:

For tough stage application...

we improved the stability of the jacket on the 4.0 mm² ELEPHANT-series. It is flexible, robust, treadable, easy to wind and of course reusable. Now the jacket surface is also smoother and easier to clean. We adapted the outer diameter for easier handling with commonly used speaker multipins (CA-COM 8-pin, NL8, LKS19, EP5).

The ELEPHANT SPM1640 needs to be specially mentioned, because 8 speaker paths can be connected up to the array with only one single cable.

Application

| Professional PA/sound systems | ||

| For ELA-technology | ||

| Mobile outdoor areas (PUR-version) |

|

||

| Cables for application especially on the stage, for open air festivals, or live events. These cables are easy to wind, simple to handle and will not knot, by using in correct way, so you can't trip when being laid out on stage. They are ideal for the professional and occasional musician. |

||

| Cables for mobile application distinguish themselves through the flexible PVC jacket, a fine-stranded wire construction, high bending cycles, and a low bending radius. They are easy to wind and suitable for outdoor application. For extreme outdoor applications (transmission vehicles, transmission of sporting events, etc.) we recommend the version with a PUR or TPE-jacket. This jacket used on SOMMER CABLEs is extremely resistant to notching, is halogen-free, and also resistant to heat. |

||

| These cables are optimized for sound. The special stranding or wire stranding along with perfect shielding will provide enduring listening pleasure and perfect transmission. They are used in the studio setting, in broadcasting, and in transmission vehicles. |

||

| Cables for installation are in the first place designed for longevity and safe transmission, especially for ELA-technology. They can be wired inside buildings over long distances, but also inside audio units (amplifiers, speakers, etc.) or control cabinets. If you have special fire protection requirements, please observe the halogen-free/ PUR and FRNC symbols. |

||

| These cables can be used to transmit and control 100 V technology. Basically almost all LF- and speaker cables in our program are suitable for use in ELA-technology. We use high quality materials for the insulation, such as PE, SPVC, PUR, Hytrel, and PP. The test voltage for our LF-cables is 1200 V, the operating voltage 300 V.

The main problem in ELA-technology are the long distances to be covered. The user has to calculate them. |

||

| These cables are optimized for sound and were developed for true, i.e. electrically and acoustically linear transmission of audio signals. For example, you can connect amplifiers, speakers, CD-players, and other audio units. They are also recommended for the ambitious studio operator. |

||

Technische Daten / Technical Data

| SPM440 - SC-ELEPHANT ROBUST | ||

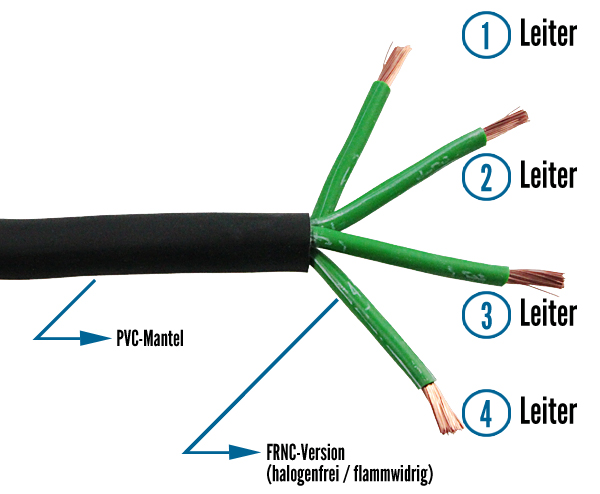

| Aufbau / | Construction: | (4LIY4,0mm2)Y |

| Cu-Litze pro Ader / | Copper strand per conductor: | 224 x 0,15 mm |

| Innen-Leiter / | Inner conductor: | 4 x 4,0 mm2 (AWG 11) |

| Material Litzen / | Material Leads: | OFC - sauerstofffreies Kupfer / Oxygen Free Copper |

| Betriebsspannung / | Operation voltage | max. 300 V |

| Leiterwiderstand bei 1 km / | Conductor resistance at 1 km: | < 4,5 Ohm |

| Isolationswiderstand bei 1 km / | Insulation Resistance at 1 km: | > 5 MOhm |

| Material Mantel (Isolation) / | Mantle material (insulation): | PVC |

| Mantel-Durchmesser / | Sheath diameter Ø: | 12,8 mm |

| Durchmesser Leiterisolation / | Wire insulation diameter Ø: | 3,75 mm |

| Temperaturbereich min.-max. / | Temperature range min-max: | -25 °C → +70 °C |

| Brandlast je m / | Fire load per m: | 0,85 kWh |

| Gewicht pro 1 m / | Weight per 1 m: | 273 g |

| Farbe / | Color: | schwarz / black |

| Hersteller-Artikel-Nr. / | Manufacturer Item no.: | 490-0051-440 |

|

||

Note

This article is sold by the meter thus the price refers to 1 meter of cable. If you need more than one meter you need to raise the amount accordingly. For example 2 items equal 2 meters of cable, 3 items equal 3 meters and so forth.

These cables are not pre-assembled which means they are delivered without connectors and such.

Scope of Delivery:

- 1 x 1m Speaker cable